PNJ Metal Manufacturing

PNJ metal manufacturing refers to the process of transforming raw metal materials into finished products through various techniques and processes. PNJ metal manufacturing has several stages to create a wide range of metal products for various industries.

Here are some common PNJ metal manufacturing processes:

1. Forming: Forming processes shape metal by applying force without removing any material.

2. Machining: Machining involves removing material from a metal workpiece to achieve the desired shape and size.

3. Welding: Welding is the process of joining two or more metal parts by melting and fusing them together.

4. Finishing: Finishing processes are used to improve the surface quality, appearance and propertied of metal products.

PNJ metal manufacturing serves a wide range of industries, including automotive, aerospace, construction, electronics, and consumer goods. Then, the specific PNJ metal manufacturing methods and techniques employed depend on factors such as the type of metal being used, the desired product, and the intended application.

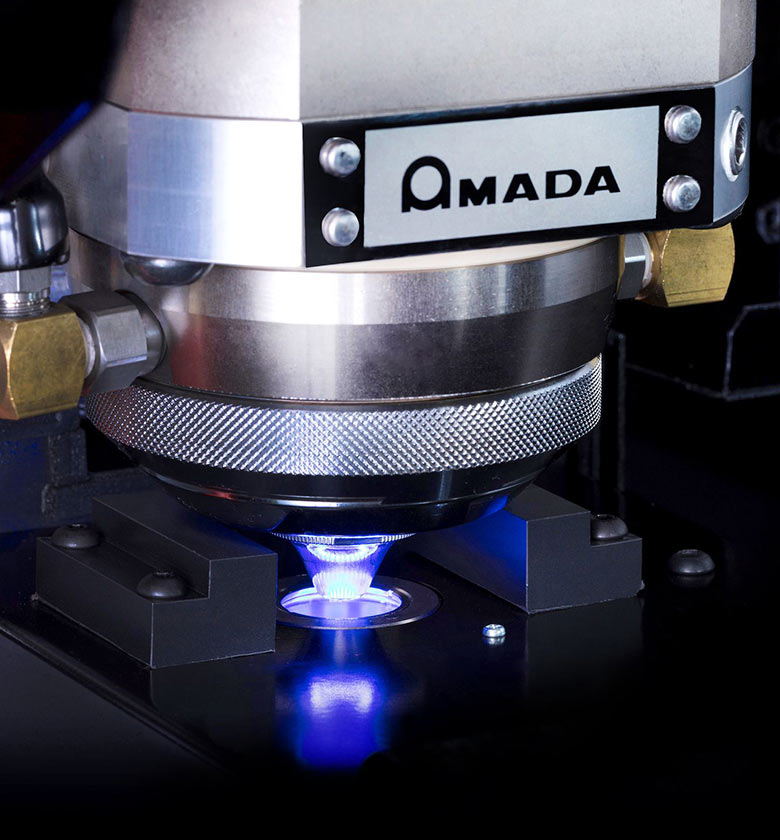

Advancements in the technology invested by PNJ metal manufacturing such as automation, robotics and machinery, have greatly influenced PNJ metal manufacturing, enabling higher precision, efficiency and customisation in the production process, that’s why PNJ metal manufacturing source specialised machines and equipment from leading machine engineers to guarantee exact precision and quality for each individual metal manufacturing process within PNJ, the selection of machinery at PNJ metal manufacturing has been carefully picked for the exact requirements of the metal manufacturing operation, the type of metal being processed, and the desired end product for the PNJ metal manufacturing customer, always ensuring to deliver quality and efficieny to each individual customer.